Стальные рельсы DIN для железных дорог — это недорогое и качественное решение.

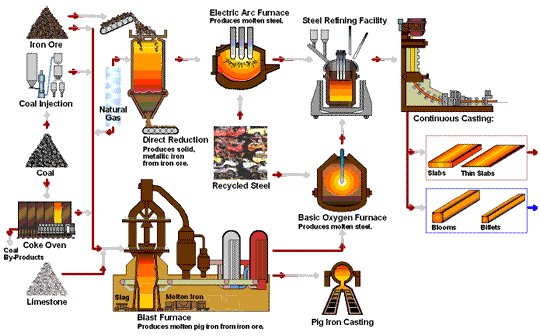

ПРОЦЕСС ПРОИЗВОДСТВА ПРОДУКТА

В нормальных условиях показатель прочности сталиперилаОн имеет такие параметры, как предел прочности на растяжение, предел текучести и относительное удлинение. В реальном производстве показатель прочности рельса, как правило, должен соответствовать национальному стандарту или стандарту железнодорожного ведомства.

Твердость стального рельса стандарта DIN относится к его способности выдерживать давление. Чем выше значение твердости, тем выше несущая способность рельса на сжатие и тем большее давление и нагрузку он может выдержать. Однако слишком высокая твердость может также привести к хрупкости рельса, поэтому необходимо найти баланс между твердостью и ударной вязкостью. В процессе изготовления рельса необходимо уделять внимание равномерности твердости лицевой и обратной стороны рельса, чтобы обеспечить его общие эксплуатационные характеристики.

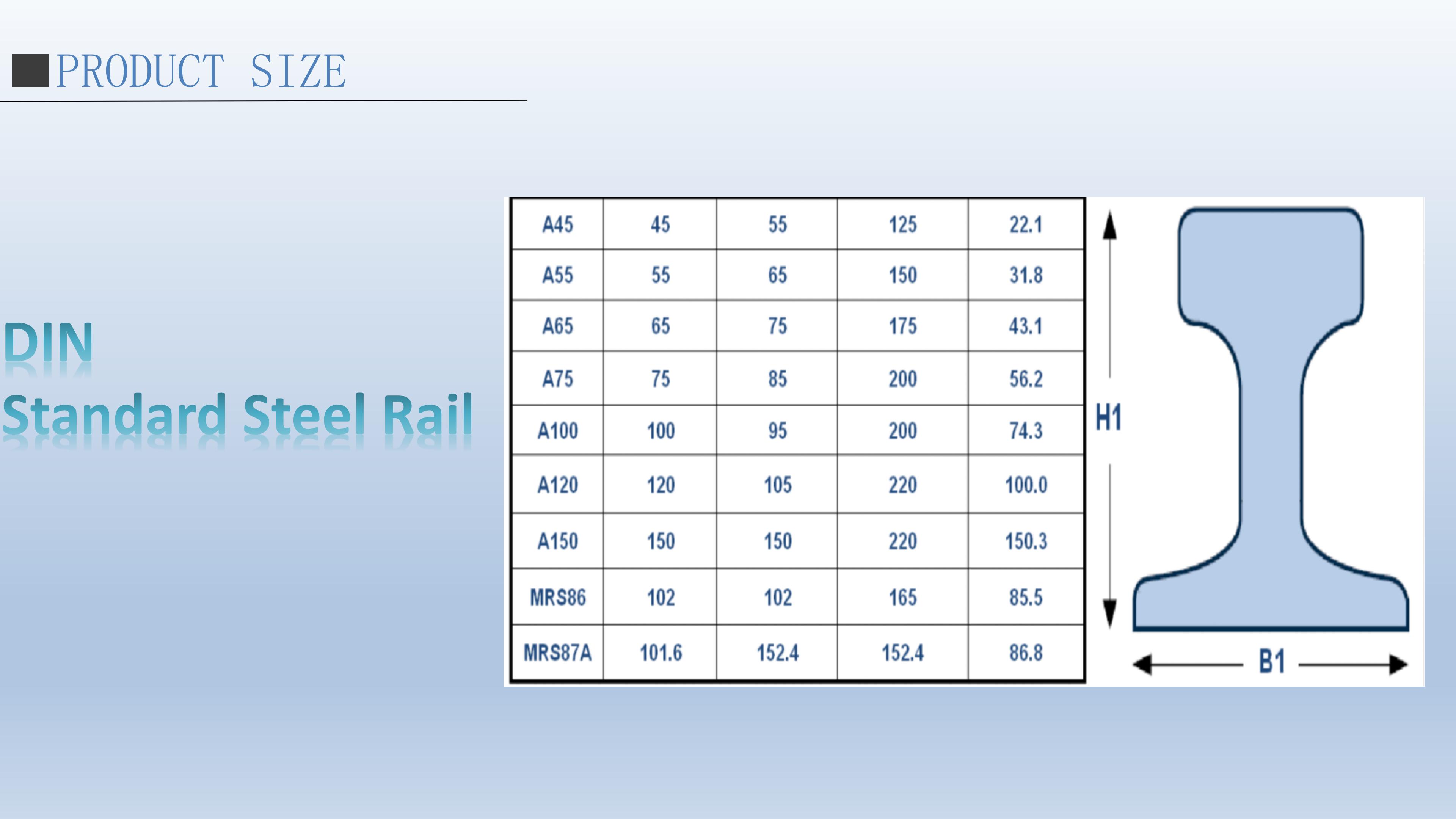

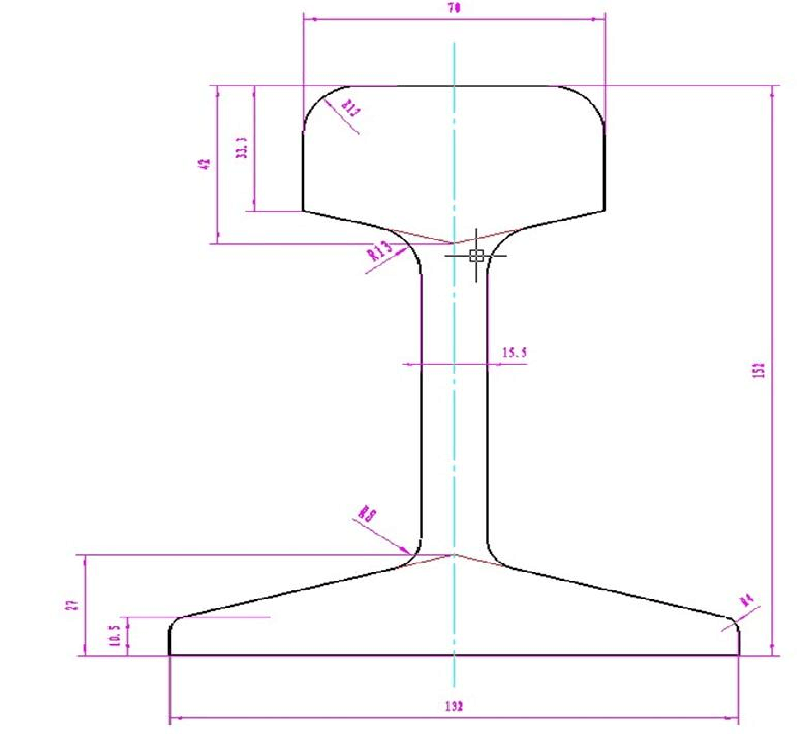

РАЗМЕР ИЗДЕЛИЯ

общийстальная железная дорогаВ США используются рельсы следующих типов: ASCE25, ASCE30, ASCE40, ASCE60, ASCE75 и другие. Эти рельсы, как правило, имеют широкое основание и крутые боковые стенки, отличаются высоким качеством поверхности, длительным сроком службы, высокой несущей способностью и другими характеристиками, подходящими для железных дорог с большой нагрузкой.

| стальная направляющая стандарта DIN | ||||

| модель | Ширина головки K (мм) | Высота направляющей H1 (мм) | Ширина дна B1 (мм) | Вес в метрах (кг/м) |

| А45 | 45 | 55 | 125 | 22.1 |

| А55 | 55 | 65 | 150 | 31.8 |

| А65 | 65 | 75 | 175 | 43.1 |

| А75 | 75 | 85 | 200 | 56.2 |

| А100 | 100 | 95 | 200 | 74.3 |

| А120 | 120 | 105 | 220 | 100.0 |

| А150 | 150 | 150 | 220 | 150.3 |

| МРС86 | 102 | 102 | 165 | 85,5 |

| МРС87А | 101.6 | 152.4 | 152.4 | 86.8 |

Немецкие стандартные рельсы:

Технические характеристики: A55, A65, A75, A100, A120, S10, S14, S18, S20, S30, S33, S41R10, S41R14, S49

Стандарт: DIN536 DIN5901-1955

Материал: ASSZ-1/U75V/U71Mn/1100/900A/700

Длина: 8-25 м

ФУНКЦИИ

ПРИЛОЖЕНИЕ

Светстальная железная дорогаРельсы длиной 10 м в основном используются для прокладки временных транспортных и локомотивных путей в лесных массивах, районах добычи полезных ископаемых, на заводах и строительных площадках. Материал: 55Q/Q235B, стандарт качества: GB11264-89.

УПАКОВКА И ДОСТАВКА

Рельсы в процессе длительной эксплуатации подвергаются износу и усталости, поэтому они должны обладать определенной износостойкостью. На износостойкость в основном влияют качество стали, качество поверхности, технология термообработки и другие факторы. Улучшение шероховатости поверхности, твердости, ударной вязкости и других параметров рельсов может значительно повысить их износостойкость.

КОНСТРУКЦИЯ ИЗДЕЛИЯ

Прочность рельса определяется его устойчивостью к ударным нагрузкам. Чем выше прочность, тем сильнее способность рельса противостоять ударным повреждениям и тем лучше он обеспечивает безопасность поезда и пассажиров. Поэтому в процессе производства рельсов необходимо контролировать процесс плавки, термообработки и другие этапы, чтобы гарантировать соответствие прочности рельса требуемым параметрам.

Часто задаваемые вопросы

1. Как я могу получить от вас ценовое предложение?

Вы можете оставить нам сообщение, и мы ответим на каждое сообщение в кратчайшие сроки.

2. Вы доставите товар вовремя?

Да, мы обещаем предоставлять продукцию высочайшего качества и доставлять её в срок. Честность — наш главный принцип.

3. Могу ли я получить образцы перед оформлением заказа?

Да, конечно. Обычно наши образцы бесплатны, мы можем изготовить продукцию по вашим образцам или техническим чертежам.

4. Каковы ваши условия оплаты?

Обычно мы используем следующие условия оплаты: 30% предоплата, остальная сумма — по предъявлении коносамента. Условия поставки: EXW, FOB, CFR, CIF.

5. Вы согласны на проведение проверки третьей стороной?

Да, безусловно, мы принимаем.

6. В чём заключается наше доверие к вашей компании?

Мы много лет специализируемся на сталелитейном бизнесе, являясь надежным поставщиком. Наш головной офис расположен в провинции Тяньцзинь. Приглашаем вас к сотрудничеству в любых вопросах.