Стальные рельсы британского стандарта

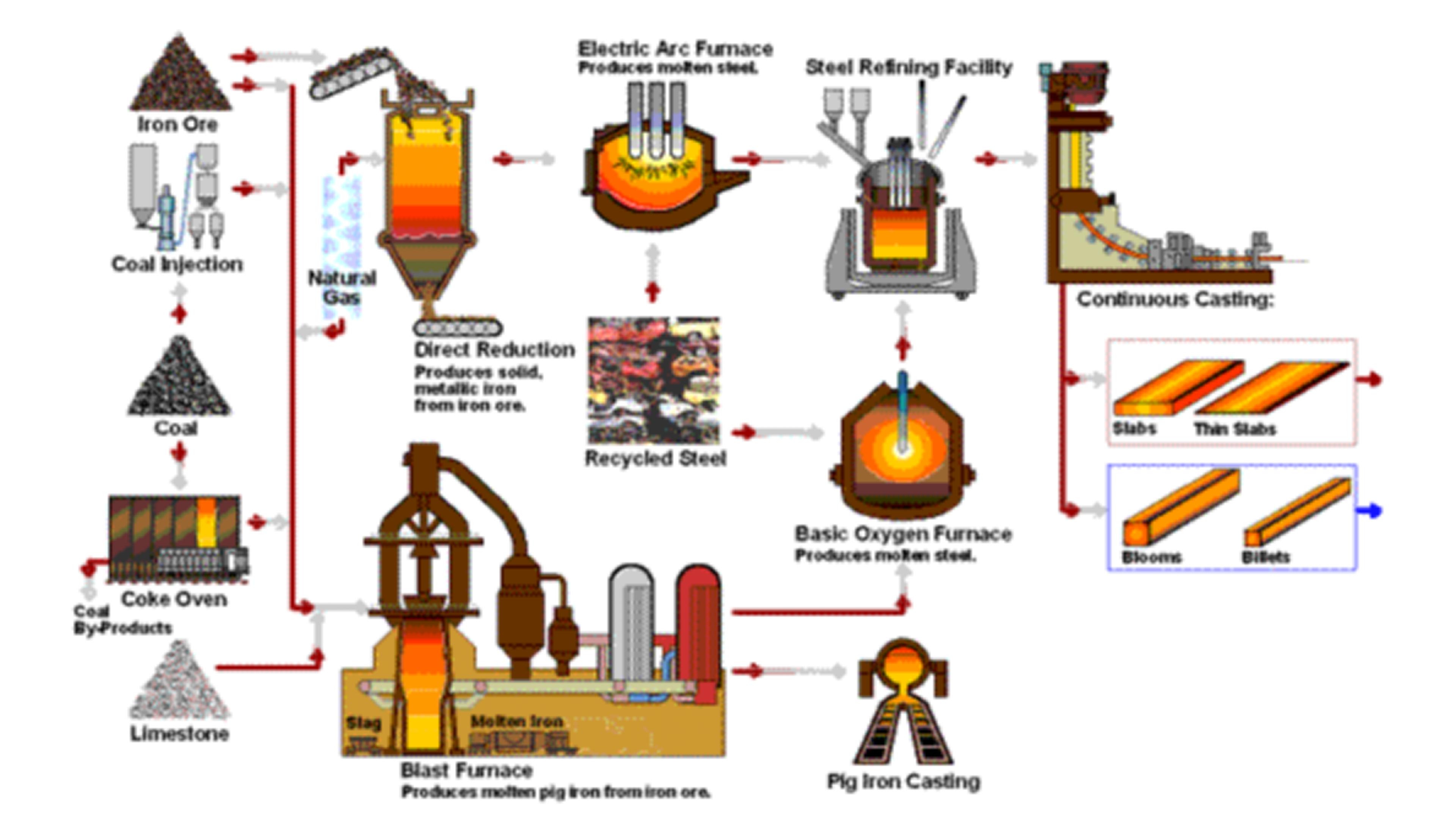

ПРОЦЕСС ПРОИЗВОДСТВА ПРОДУКТА

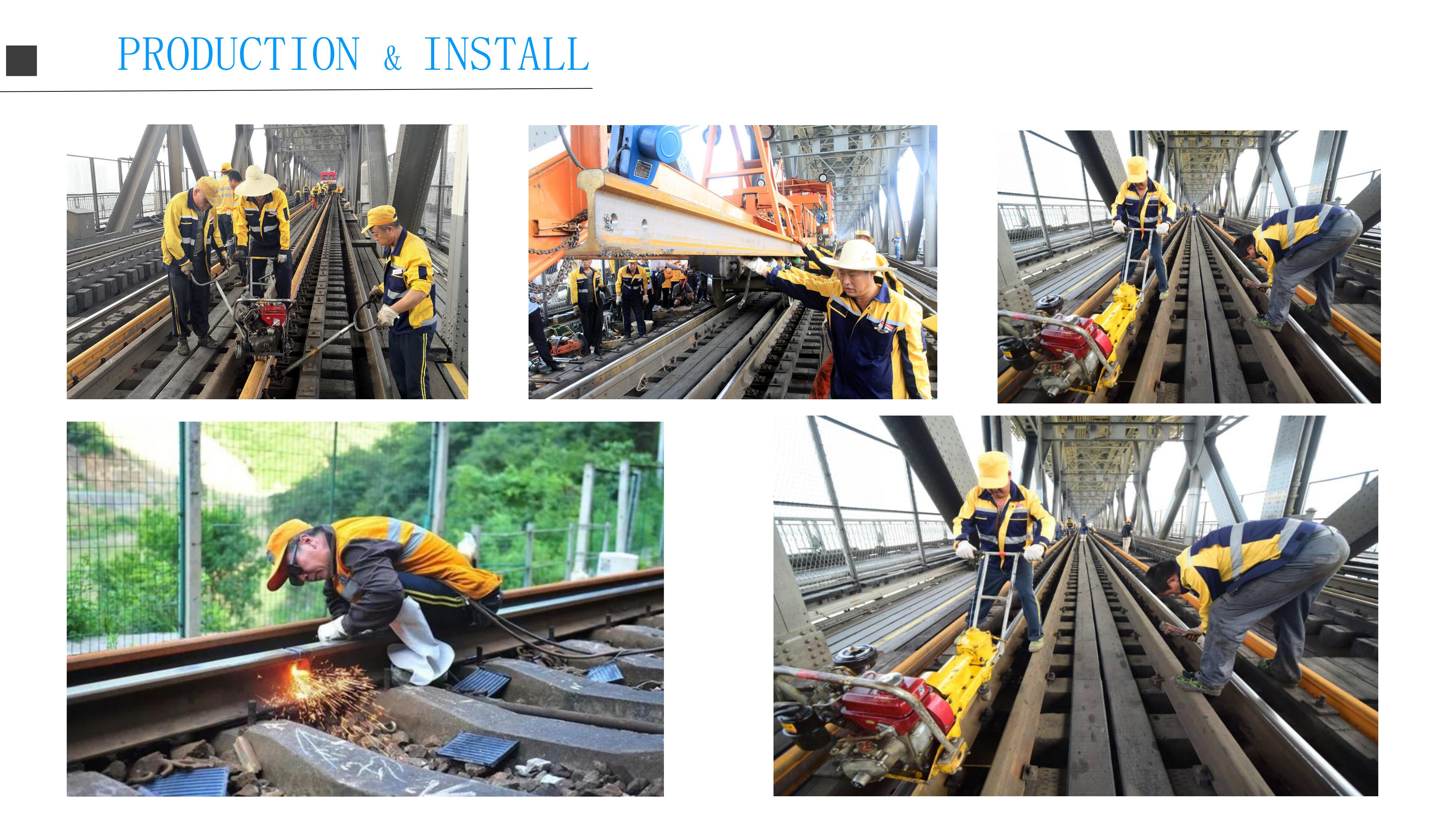

Технология и процесс строительства

Процесс строительствакитайские стальные рельсыПроектирование железнодорожных путей требует высокой точности и тщательного учета различных факторов. Начинается все с разработки схемы путей, учитывающей предполагаемое использование, скорость движения поездов и рельеф местности. После завершения проектирования начинается процесс строительства, включающий следующие ключевые этапы:

1. Земляные работы и закладка фундамента: Строительная бригада подготавливает грунт, выкапывая котлован и создавая прочный фундамент, способный выдерживать вес и нагрузку от поездов.

2. Укладка балласта: На подготовленную поверхность укладывается слой щебня, известный как балласт. Он служит амортизирующим слоем, обеспечивая устойчивость и помогая равномерно распределять нагрузку.

3. Шпалы и крепление: Затем поверх балласта устанавливаются деревянные или бетонные шпалы, имитирующие каркасную конструкцию. Эти шпалы обеспечивают надежную основу для стальных железнодорожных путей. Они крепятся с помощью специальных гвоздей или зажимов, обеспечивая их прочную фиксацию.

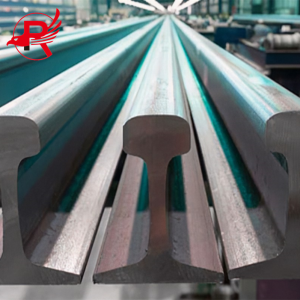

4. Укладка рельсов: Стальные железнодорожные рельсы длиной 10 м, часто называемые стандартными рельсами, тщательно укладываются поверх шпал. Изготовленные из высококачественной стали, эти рельсы обладают исключительной прочностью и долговечностью.

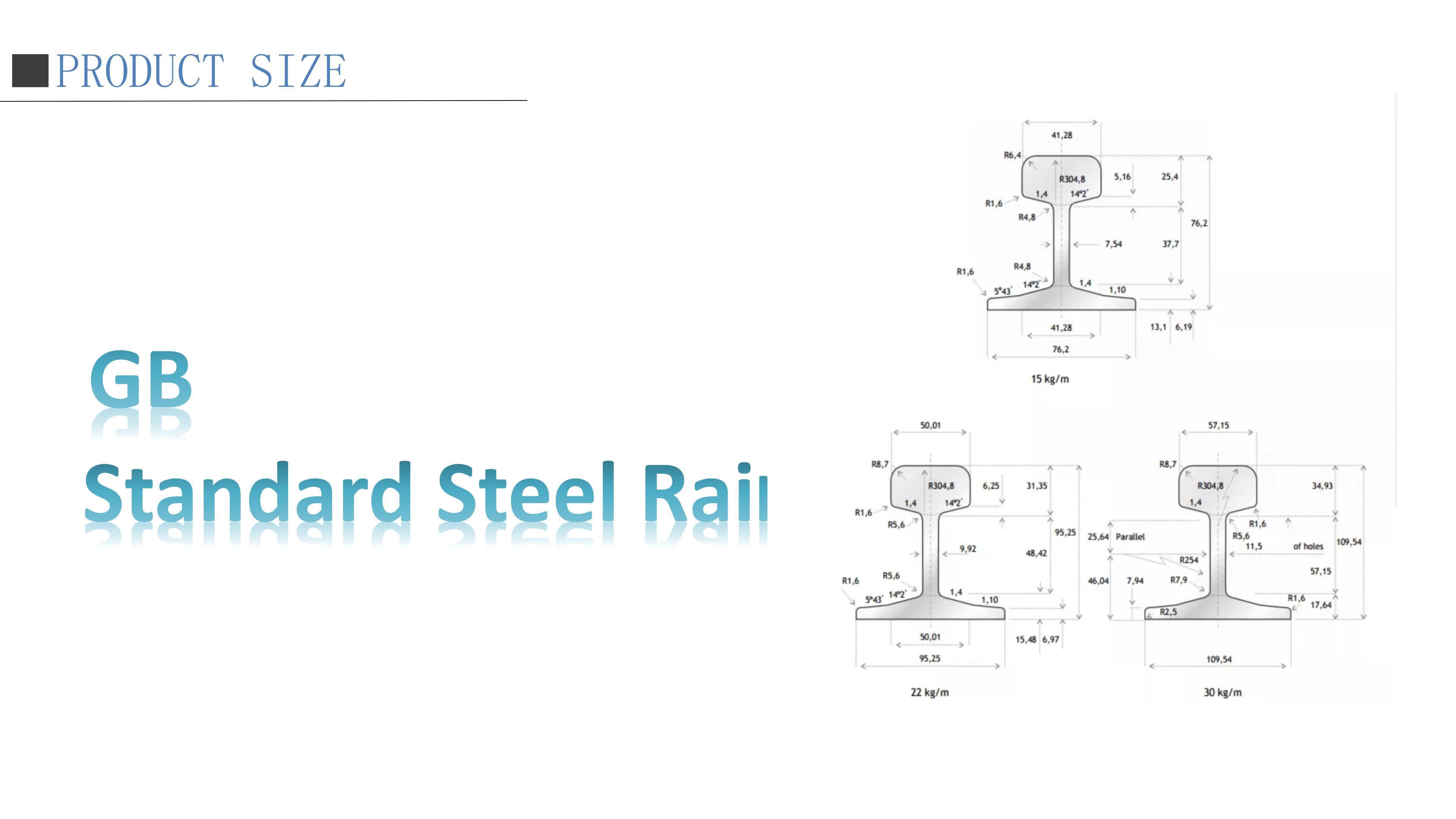

РАЗМЕР ИЗДЕЛИЯ

| Название продукта: | Стальные рельсы британского стандарта | |||

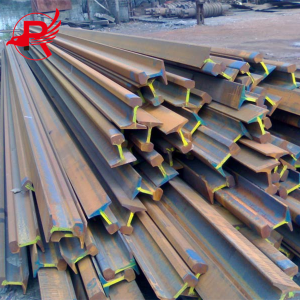

| Тип: | Тяжелые рельсы, крановые рельсы, легкие рельсы | |||

| Материал/Характеристики: | ||||

| Скоростной трамвай: | Модель/Материал: | Q235, 55Q; | Технические характеристики: | 30 кг/м, 24 кг/м, 22 кг/м, 18 кг/м, 15 кг/м, 12 кг/м, 8 кг/м. |

| Тяжелые рельсы: | Модель/Материал: | 45MN, 71MN; | Технические характеристики: | 50 кг/м, 43 кг/м, 38 кг/м, 33 кг/м. |

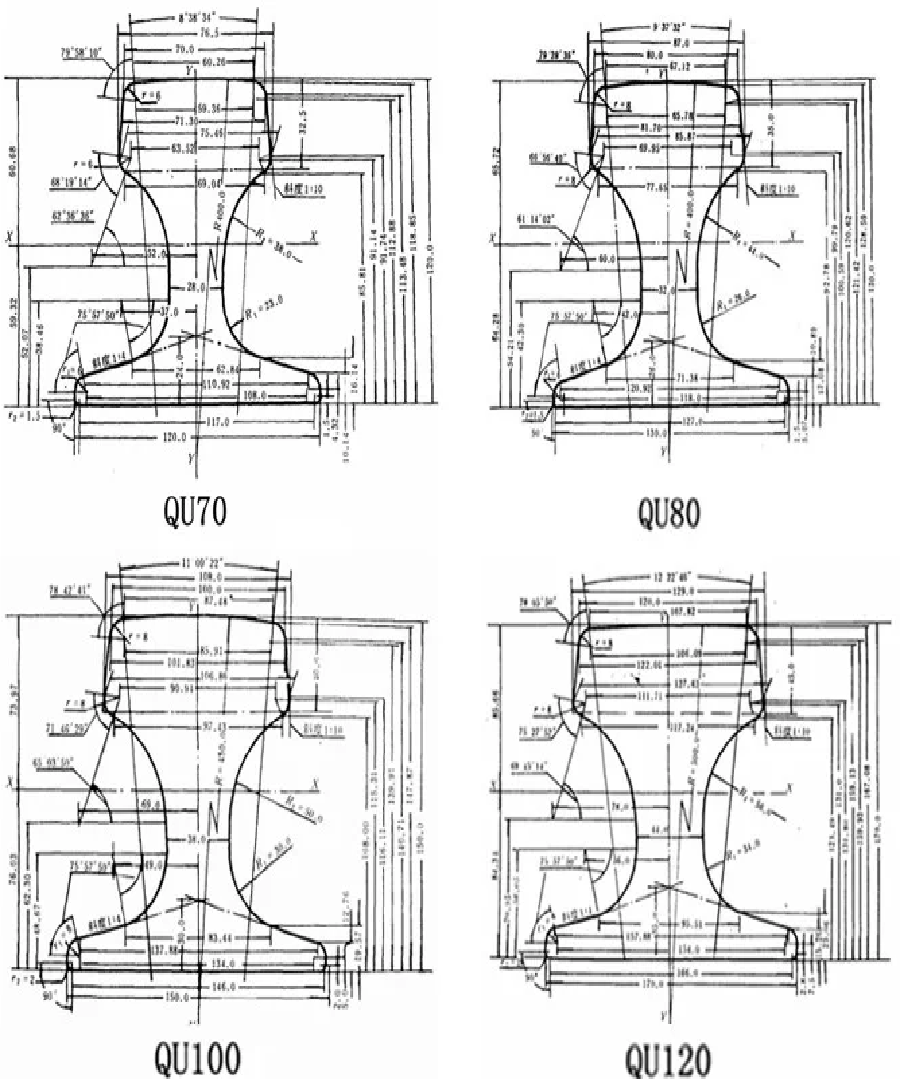

| Крановый рельс: | Модель/Материал: | U71MN; | Технические характеристики: | QU70 кг/м, QU80 кг/м, QU100 кг/м, QU120 кг/м. |

Стальные рельсы британского стандарта:

Технические характеристики: GB6 кг, 8 кг, GB9 кг, GB12, GB15 кг, 18 кг, GB22 кг, 24 кг, GB30, P38 кг, P43 кг, P50 кг, P60 кг, QU70, QU80, QU100, QU120

Стандарт: GB11264-89 GB2585-2007 YB/T5055-93

Материал: U71Mn/50Mn

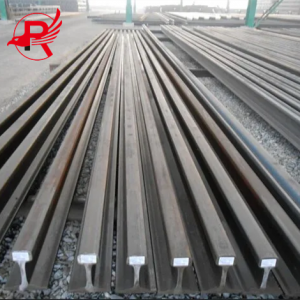

Длина: 6–12 м, 12,5–25 м

| Товар | Оценка | Размер сечения (мм) | ||||

| Высота рельса | Ширина основания | Ширина головы | Толщина | Вес (кг) | ||

| Скоростной трамвай | 8 кг/м | 65.00 | 54.00 | 25.00 | 7.00 | 8.42 |

| 12 кг/м | 69.85 | 69.85 | 38.10 | 7.54 | 12.2 | |

| 15 кг/м | 79.37 | 79.37 | 42.86 | 8.33 | 15.2 | |

| 18 кг/м | 90.00 | 80.00 | 40.00 | 10.00 | 18.06 | |

| 22 кг/м | 93.66 | 93.66 | 50.80 | 10.72 | 22.3 | |

| 24 кг/м | 107.95 | 92.00 | 51.00 | 10.90 | 24.46 | |

| 30 кг/м | 107.95 | 107.95 | 60.33 | 12.30 | 30.10 | |

| Тяжелые железные дороги | 38 кг/м | 134.00 | 114.00 | 68.00 | 13.00 | 38.733 |

| 43 кг/м | 140.00 | 114.00 | 70.00 | 14.50 | 44.653 | |

| 50 кг/м | 152.00 | 132.00 | 70.00 | 15.50 | 51.514 | |

| 60 кг/м | 176.00 | 150.00 | 75.00 | 20.00 | 74.64 | |

| 75 кг/м | 192.00 | 150.00 | 75.00 | 20.00 | 74.64 | |

| UIC54 | 159.00 | 140.00 | 70.00 | 16.00 | 54.43 | |

| UIC60 | 172.00 | 150.00 | 74.30 | 16.50 | 60.21 | |

| Подъемная направляющая | QU70 | 120.00 | 120.00 | 70.00 | 28.00 | 52.80 |

| QU80 | 130.00 | 130.00 | 80.00 | 32.00 | 63.69 | |

| QU100 | 150.00 | 150.00 | 100.00 | 38.00 | 88.96 | |

| QU120 | 170.00 | 170.00 | 120.00 | 44.00 | 118.1 | |

ПРЕИМУЩЕСТВО

рельсы поездаРельсы являются основными несущими элементами высокоскоростных поездов. Они несут вес и нагрузку поезда, а также выдерживают удары и трение, вызванные атмосферным давлением, землетрясениями и другими транспортными и природными нагрузками. Поверхность рельсов изготовлена из износостойких материалов, обладающих хорошими противоизносными свойствами и способных противостоять износу колесных пар и тяжеловесных грузов, что продлевает срок их службы.

1.1 Высокая прочность

Материал рельсов — высококачественная сталь, обладающая высокой прочностью и ударной вязкостью. В экстремальных условиях, таких как большие нагрузки и длительная эксплуатация поездов, она способна выдерживать значительное давление и деформацию, обеспечивая безопасность и стабильность железнодорожного транспорта.

1.2 Хорошая износостойкость

Поверхность рельса обладает высокой твердостью и эффективно противостоит износу от колес. Одновременно с этим, технические характеристики и технологии изготовления рельсов были усовершенствованы за прошедшие годы, что позволило снизить износ отдельных частей и продлить срок их службы.

1.3 Простота в обслуживании

Общая конструкция рельсов очень устойчива и относительно проста в обслуживании, что позволяет значительно снизить помехи и повреждения железнодорожных путей.

ПРОЕКТ

Наша компания's китайский поставщик рельсовВ порту Тяньцзиня одновременно было отгружено 13 800 тонн стальных рельсов, экспортируемых в США. Строительный проект был завершен укладкой последнего рельса на железнодорожную линию. Все эти рельсы изготовлены на универсальной производственной линии нашего завода по производству рельсов и стальных балок с использованием самых высоких и строгих технических стандартов, соответствующих мировым стандартам.

Для получения более подробной информации о железнодорожной продукции, пожалуйста, свяжитесь с нами!

WeChat: +86 13652091506

Тел.: +86 13652091506

Электронная почта:[email protected]

ПРИЛОЖЕНИЕ

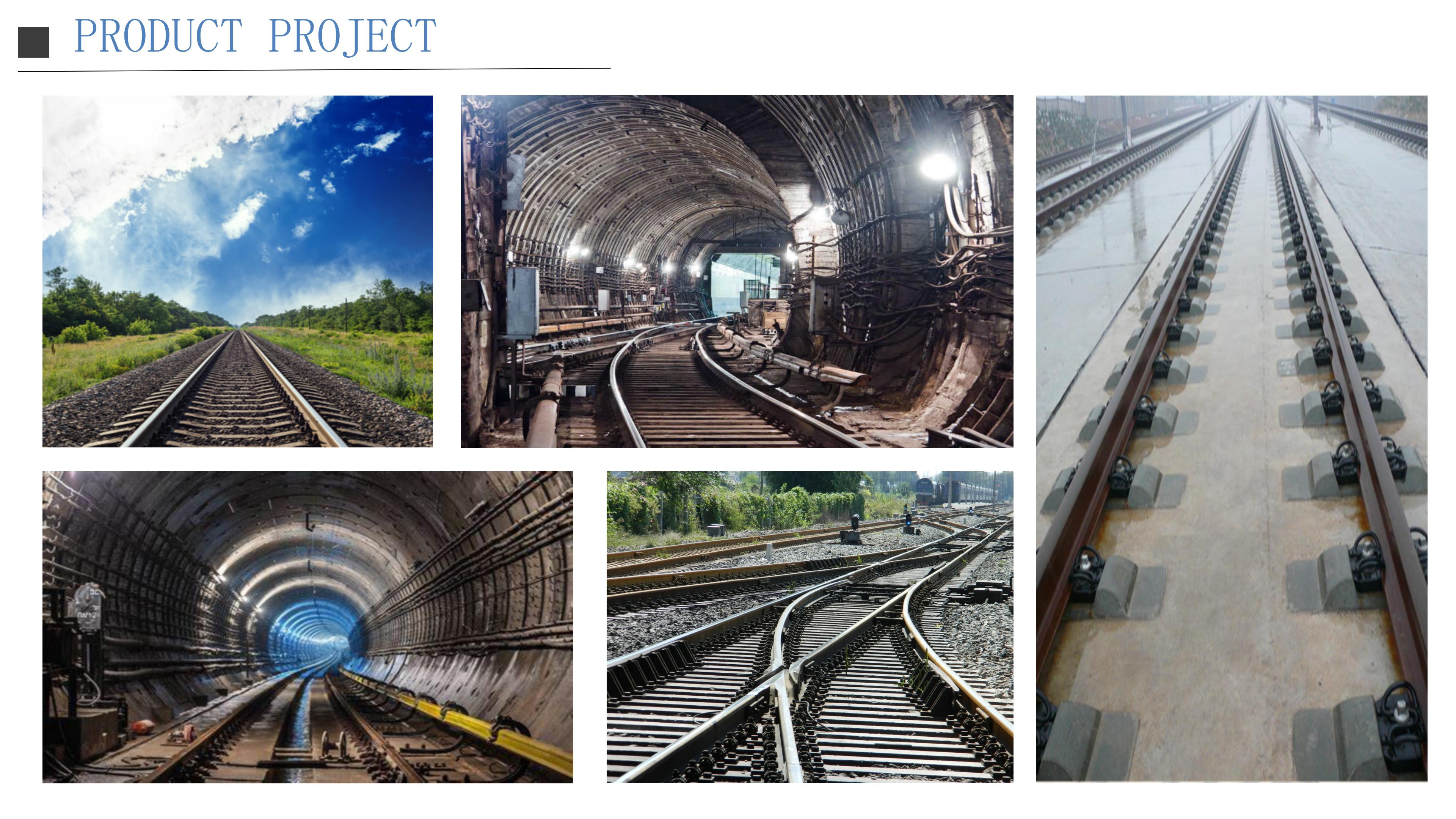

Железнодорожный транспорт: Рельсы — это инфраструктура железнодорожной системы, используемая для поддержки и направления поездов. Они образуют систему путей, по которым движется поезд, и выдерживают вес и рабочее давление поезда.

Системы метро и легкорельсового транспорта: Стальные рельсы также используются в системах метро и легкорельсового транспорта в качестве путей для движения поездов. Эти системы, как правило, используются для скоростного транспорта внутри городов, где рельсы играют важную роль.

1. Сфера железнодорожного транспорта

Рельсы являются неотъемлемой и важной составляющей железнодорожного строительства и эксплуатации. В железнодорожном транспорте стальные рельсы отвечают за поддержку и переноску всего веса поезда, и их качество и характеристики напрямую влияют на безопасность и устойчивость поезда. Поэтому рельсы должны обладать превосходными физико-химическими свойствами, такими как высокая прочность, износостойкость и коррозионная стойкость. В настоящее время стандартом для рельсов, используемым большинством отечественных железнодорожных линий, является GB/T 699-1999 «Высокоуглеродистая конструкционная сталь».

2. Строительная инженерия

Помимо железнодорожного транспорта, стальные рельсы широко используются в строительстве, например, при возведении кранов, башенных кранов, мостов и подземных сооружений. В этих проектах рельсы используются в качестве опор и элементов, поддерживающих и выдерживающих вес. Их качество и прочность оказывают решающее влияние на безопасность и устойчивость всего строительного проекта.

3. Область применения тяжелой техники

В области производства тяжелого машиностроения рельсы также являются распространенным компонентом, используемым в основном на рельсовых путях. Например, в сталелитейных цехах металлургических заводов, на производственных линиях автомобильных заводов и т. д. необходимы рельсовые пути для поддержки и перемещения тяжелых машин и оборудования весом в десятки тонн и более.

УПАКОВКА И ДОСТАВКА

Железнодорожные перевозки: Железнодорожные перевозки являются наиболее распространенным методом железнодорожных перевозок. Рельсы могут транспортироваться на большие расстояния по выделенным железнодорожным линиям или грузовым железнодорожным поездам. Этот метод быстрый, эффективный и подходит для перевозки больших объемов грузов.

Автомобильный транспорт: Для железнодорожных перевозок на короткие расстояния или в небольших масштабах можно использовать автомобильный транспорт с помощью грузовиков или прицепов. Этот метод является гибким и подходит для небольших транспортных нужд.

Морские перевозки: Для трансграничных перевозок или транспортировки рельсов через моря, они могут осуществляться морским путем. Рельсы обычно перевозятся в контейнерах на грузовых судах для морских перевозок.

Внутренний водный транспорт: В некоторых районах, особенно при реализации инженерных проектов вдоль внутренних рек, для перевозки железнодорожных путей может использоваться внутренний водный транспорт. Этот метод подходит для конкретных географических условий.

Производство рельсов для высокоскоростных железных дорог включает в себя множество сложных процессов, в том числе подготовку сырья, выплавку стали, непрерывную разливку, прокатку и термообработку. Процесс производства рельсов для высокоскоростных железных дорог особенно сложен, особенно для рельсов средних и высоких скоростей, которые должны соответствовать множеству показателей, таких как высокая прочность, износостойкость, коррозионная стойкость и хорошая прямолинейность. Это требует использования точных форм и передовых технологий прокатки. В то же время, рельсы для высокоскоростных железных дорог должны проходить строгие испытания качества, чтобы гарантировать соответствие каждого рельса соответствующим национальным стандартам и требованиям. Применение этих технологий позволило вывести процесс производства рельсов для высокоскоростных железных дорог на мировой уровень.

СИЛЫ КОМПАНИИ

Сделано в Китае, первоклассное обслуживание, высочайшее качество, мировая известность.

1. Эффект масштаба: Наша компания обладает разветвленной цепочкой поставок и крупным сталелитейным заводом, что позволяет нам достигать эффекта масштаба в транспортировке и закупках, и стать сталелитейной компанией, интегрирующей производство и услуги.

2. Разнообразие продукции: Разнообразие продукции позволяет приобрести у нас любую необходимую вам сталь. Мы специализируемся на стальных конструкциях, стальных рельсах, стальных шпунтовых сваях, кронштейнах для фотоэлектрических систем, швеллерах, рулонах кремниевой стали и другой продукции, что обеспечивает большую гибкость при выборе необходимого типа продукции для удовлетворения различных потребностей.

3. Стабильные поставки: Более стабильная производственная линия и цепочка поставок могут обеспечить более надежные поставки. Это особенно важно для покупателей, которым требуются большие объемы стали.

4. Влияние бренда: Обладает более высоким влиянием бренда и большей рыночной долей.

5. Сервис: Крупная сталелитейная компания, объединяющая в себе услуги по индивидуальному заказу, транспортировке и производству.

6. Ценовая конкурентоспособность: разумная цена

*Отправьте электронное письмо по адресу[email protected]чтобы получить ценовое предложение для ваших проектов

СИЛЫ КОМПАНИИ

Часто задаваемые вопросы

1. Как я могу получить от вас ценовое предложение?

Вы можете оставить нам сообщение, и мы ответим на каждое сообщение в кратчайшие сроки.

2. Вы доставите товар вовремя?

Да, мы обещаем предоставлять продукцию высочайшего качества и доставлять её в срок. Честность — наш главный принцип.

3. Могу ли я получить образцы перед оформлением заказа?

Да, конечно. Обычно наши образцы бесплатны, мы можем изготовить продукцию по вашим образцам или техническим чертежам.

4. Каковы ваши условия оплаты?

Обычно мы используем следующие условия оплаты: 30% предоплата, остальная сумма — по предъявлении коносамента. Условия поставки: EXW, FOB, CFR, CIF.

5. Вы согласны на проведение проверки третьей стороной?

Да, безусловно, мы принимаем.

6. В чём заключается наше доверие к вашей компании?

Мы много лет специализируемся на сталелитейном бизнесе, являясь надежным поставщиком. Наш головной офис расположен в провинции Тяньцзинь. Приглашаем вас к сотрудничеству в любых вопросах.